The Gas Turbine Engine for cars:-

The turbine engine has been independently researched and developed by most of the major car manufacturers including Rover , Fiat , General Motors and Chrysler. The working of a turbine engine is simple compared to that of an IC reciprocating engine . Basically it involves the pulling in and compressing of air to the engine in relatively large quantities and then expanding this air and using it to drive a power turbine. The power turbine is connected by a common shaft to the compressor turbine . About 10% of the power generated is used to turn the compressor turbine. The compressor turbine pulls air into the engine and compresses it. Compression is achieved due to the shape of the turbine blade which tends to push air out from the centre towards the edges. This air then enters a combustion chamber where fuel is added and ignited ,resulting in the rapid expansion of the gases , these are used to drive the power turbine. The engine are relatively small and compact, about half the size of a reciprocating IC engine of the same horsepower. The turbine in such an engine maybe about 4" - 5" in diameter , while the compressor turbine would be from 7" - 10" in diameter. The power output from such an engine can reach 250 horsepower. So why didn't turbines catch on. The answer is that turbines because they use continuous combustion of fuel need about 8 times the fuel that a reciprocating IC engine needs.

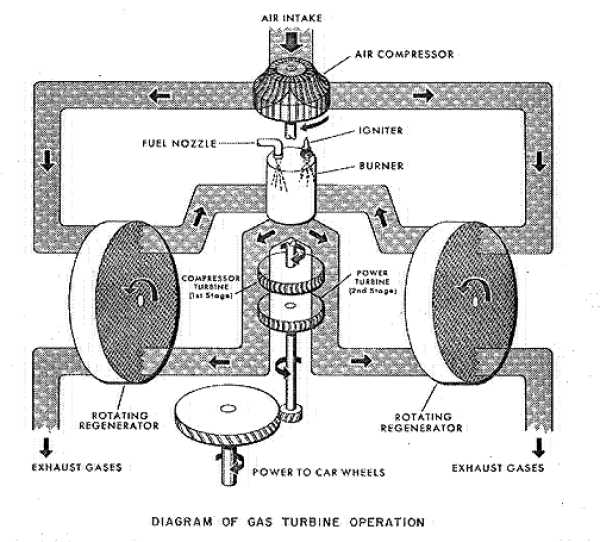

Given below are diagrams of the layout of the turbine engine used by Chrysler and some facts about the engine.

HOW THE GAS TURBINE OPERATES

When the turbine engine is operating, the first- stage turbine rotates the centrifugal compressor run impeller to draw in air and compress it. The compressed air is heated as it passes through the high-pressure side of the regenerators, and then it enters a combustion chamber (burner) in to which fuel is injected and ignited. The burning fuel raises the temperature of the gases (a mixture of combustion products and air) and increases their energy level. These hot gases pass through the first-stage turbine driving the compressor and then through the second- stage turbine (power turbine) which drives the car. The gases leaving the power turbine pass through the low-pressure side of the regenerators, giving up heat to the regenerator honeycomb, and flow out the exhaust ducts.

With two small regenerators, the engine is compact and has balanced temperature gradients on both sides. Intake air from the compressor is split into two paths, which pass through the regenerators and come together again at the burner. The hot gases from the burner, after going through the two turbine stages, also are split into two paths to flow through the two regenerators and then out through the exhaust ducts.

The compressor and first-stage turbine, along with the burner and regenerator, are called the "gas generator" section of the engine since these components produce the hot gases that power the engine.

'The two turbine wheels are not interconnected mechanically, and thus one may rotate while the other is stationary. The first-stage turbine always rotates while the engine is operating, its speed varying from 18-22, 000 rpm at idle up to about 44, 600 rpm at rated power. 'The second-stage turbine, being connected directly to the car's drive train, rotates only while the car is in motion. Its speed ranges from zero at standstill to a maximum of about 45, 700 rpm. Since the power turbine is rotated by hot gases and is not mechanically connected to the gas generator rotor, the power turbine stops whenever the car stops, and the gas generator continues idling. Thus the engine will not stall under overload.

ADVANTAGES of the GAS TURBINE ENGINE

1) Simplicity...............Number of parts reduced 80%

2) Vibrationless...............Rotary motion instead of reciprocating

3) Exhaust gases cool, clean...............Excess air flows through engine, fuel completely nontoxic burned, practically no carbon

monoxide

4) Overload won't "kill" the engine...............Compressor and first-stage turbine rotate independently of power turbine --keep on

idling even if sudden overload stops power turbine

5) Light, compact...............Few parts

6) Dependable low-temperature starting...............Low friction--fuel injected directly into combustion chamber--igniter fires repeatedly- -timing not important- -vaporization not critical

7) No warm-up period needed...............Can operate under full power if desired as soon as fuel is burning steadily

8) Instant heat available in winter...............Hot gases immediately available as soon as engine is operating under own power--no

cylinder block and coolant to heat up first

9) Negligible oil consumption...............No pistons or cylinder walls to lubricate

10)Antifreeze not required...............Temperature controlled by air flowing through engine--therefore no water, no antifreeze

11) Operates on wide variety of fuels...............Less limited by vaporization or detonation characteristics of fuel

12) Less maintenance...............No tune-ups required--less friction and wear- -fewer parts- -no valves, camshaft, distributor, etc.

A Cut-away view of the Chrysler Gas Turbine Engine:- Some facts about the Chrysler Gas Turbine engine:- The Chrysler regenerative gas turbine engine has two independent turbine wheels, one driving the compressor and accessories and one driving the car. It is a "regenerative" turbine because it utilizes two rotating heat exchangers--called regenerators--to

recover heat from the exhaust gases, thus boosting fuel economy and reducing exhaust temperature. The two regenerators rotate in vertical planes, one on each side of the engine.

Performance Rating

The gas turbine engine is rated at 130 horsepower at 3600 rpm output shaft speed and 425 lb-ft torque at zero output shaft speed under ambient temperature and atmospheric pressure conditions of 85 F and 29.92" Hg, respectively. However, unlike a piston engine, which is tested and rated as an individual unit without transmission or accessories, the gas turbine power plant is rated as a complete package including transmission and accessories. 'Ihus , owing to rating methods and torque characteristics,

the 130-hp turbine power plant gives performance comparable to a piston engine rated at 200-hp or more.

|